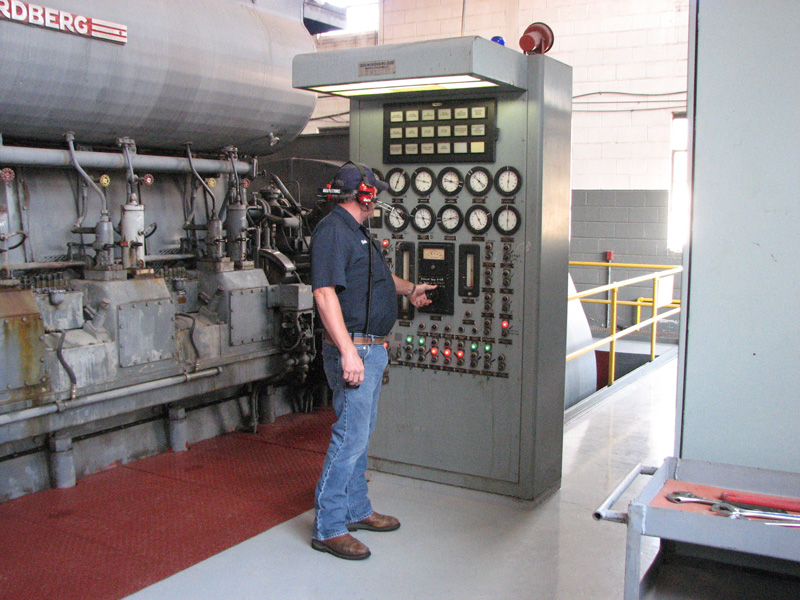

The Kennett, Missouri Power Station required upgrading of the emission control system on the power plant’s internal combustion engines to meet the EPA RICE NESHAP* standard.

*Reciprocating Internal Combustion Engine National Emission Standards for Hazardous Air Pollutants

DCL developed and manufactured a series of low emission catalytic silencers which matched the footprint of the original silencers, minimizing the time and cost involved with installation of the new catalytic silencers. The DCL catalyst used in the silencers was optimized for low exhaust temperature 2-stroke engines and was tailored to meet the plants specific emissions requirements. The design of the elements allows easy access for maintenance using the integrated, heavy-duty hinged side access doors.

With the catalytic silencers successfully installed the Kennett power plant is now meeting the required emission and noise standards for the facility.

| Engine | Nordberg TSGL-2112-SC |

| Power | 8725 hp |

| Flow | 79000 acfm @470 °F |

| Fuel | Diesel/Natural Gas (dual fuel) |

| Sound Attenuation | 18-25 dBA insertion loss |

| Material | Mild steel |

| Catalyst Efficiency | > 70% CO destruction |