REPLACEMENT ELEMENTS

DCL's Metalcor® catalyst elements are thin-walled metallic catalyst substrate for stationary engines. Metalcor® catalyst elements are a perfect fit for both DCL housings and competitor's housings. As a result of DCL's manufacturing expertise, Metalcor® catalyst elements are available in hundreds of shapes and sizes. Most elements are in stock and ready for same day shipment.

FEATURES

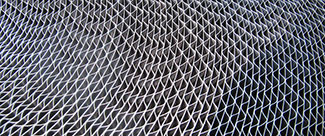

- Uses DCL original part technology, ensuring high emission reduction performance.

- Thin walled metal cell structure available in a variety of cell densities for optimum emission performance and pressure drop.

- Flexible manufacturing allows production of a variety of substrate shapes, including round, rectangular, octagonal, and race-tracked.

- Premium grade metallic substrate structure capable of high temperature operation.

- Solid brazed substrates available for heavy-duty applications with high thermal and mechanical stress.

- Catalytic coatings optimized for applications such as lean-burn oxidation, diesel oxidation, volatile organic compound (VOC) destruction, and three-way catalysts (NSCR - non-selective catalytic reduction).

PERFORMANCE PROMISE

DCL's engineered catalytic silencers are designed for long term, problem free operation under the harshest environments for heat, vibration and catalyst fouling. DCL has a range of experience with modern high speed engines as well as older legacy engines, compressor integrals, engines with high oil consumption, and a wide variety of liquid and gaseous fuels. DCL backs every stationary engine catalytic silencer with an emission and noise performance guarantee, providing you worry free compliance with environmental operating permits.

DCL sales professionals are strategically situated across North America and Europe to provide local emissions regulation expertise as well as expert product knowledge and sales support wherever you need it. For assistance sizing and selecting the right catalytic silencer for your needs, contact a DCL sales professional.